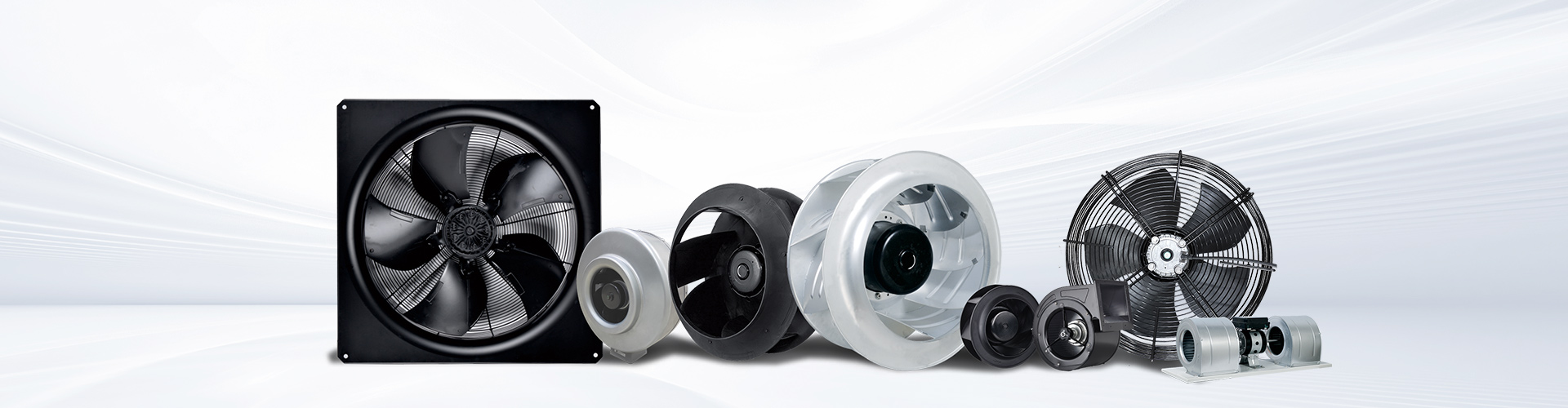

Forward centrifugal fans have a blade exit angle of more than 90°. When working, the impeller rotates at high speed to generate centrifugal force, which throws the air from the center to the edge, and discharges it through the pressurization of the worm casing, and at the same time, negative pressure is formed inside the impeller to continuously absorb the air. Widely used in ventilation and air conditioning, industrial gas transportation, dust removal and equipment supporting and other fields, especially in the high-pressure, small air volume scenarios with outstanding advantages, can meet the needs of multi-industry gas treatment.

Backward centrifugal fan in the work, the airflow from the fan axial into the blade space, and then driven by the impeller on the one hand with the impeller rotation; on the other hand in the role of inertia to improve the energy, along the radius of the direction of the impeller to leave the fan, relying on the centrifugal force generated to do the work of the fan is called centrifugal fan.

Axial fan is a kind of ventilation equipment which conveys gas through axial flow, and its core impeller is composed of hub and twisted blades. When working, the motor drives the impeller to rotate, and the blades push the gas to flow along the axial direction (parallel to the direction of the rotating axis), and the gas flows directly from the inlet end to the outlet end of the fan, and the flow direction is basically unchanged, which is similar to the principle of propeller propulsion.